G3 ADDITIVE MANUFACTURING | Your Ideas to Reality

G3 ADDITIVE MANUFACTURING | Your Ideas to Reality

Fused Deposition Modeling (FDM) is a popular 3D printing technology that falls under the umbrella of additive manufacturing. It is widely used in prototyping and small-scale production because it is relatively inexpensive and easy to use. It can create objects with complex geometries in almost any material imaginable.

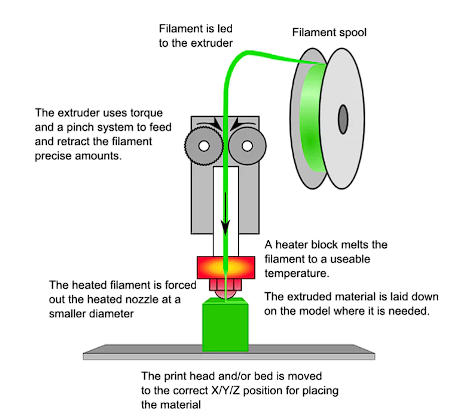

In FDM 3D printing, a thermoplastic filament is fed into a printer head, which heats the filament until it reaches its melting point. The melted plastic is then extruded through a nozzle and deposited layer by layer onto a build platform, where it solidifies and fuses with the previous layer. This process continues until the object is complete.

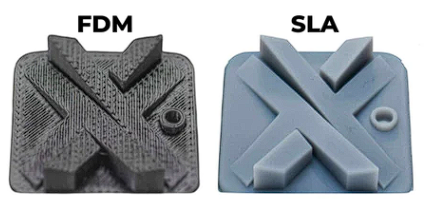

FDM 3D printing may not be the best choice for creating highly detailed or smooth-surfaced objects, as the layer-by-layer deposition process can result in visible ridges and layer lines. These layer lines can vary widely with some being similar to that of SLA/SLS 3D Printing. However, FDM is generally chosen due to its large print size abilities, stronger materials, ease printing, and cheaper cost. Belwo you can see the surface quality difference between FDM and SLA (Resin 3D Printing).

FDM printers come in a wide variety of sizes and material capibilities. Most consumer grade printers will generally only use typical thermo plastics such as PLA, ABS, PETG, TPU, and Nylon with more expensive variations capable of utilizing hybrid material which may conatin carbon fiber or even glass. The print size can vary as well but generally are under 12"x12"x12" for most consumer grade machines.

The step up into the commerical/ industriual grade machines opens the door to stonger materials with some capabale of printing utilizing metals. These machine are generally more expensive and larger with some capable of printing entire vehicles. Additinally, part accuracy starts to bridge the gap between typical consumer machines and SLA machines with layer heights of around .06mm (.003in) possible. Companys are not only printing smaller prototypes but now entire homes made of special conctretes and woods to entire space craft of metals.

| Layer Line Heights | 0.05mm (.002in) - 1mm (.04in) |

| Accuracy | +/- .05mm (.002in) - +/- .4mm (.016in) |

| Print Speeds | 0-500mm/s (19.7in/s) (Depends on Printer and Materials) |

| Nozzle Temperatues | 0-450C (842F) |

| Print Bed Temperatures | 0-150C (302F) |

This site was created with the Nicepage